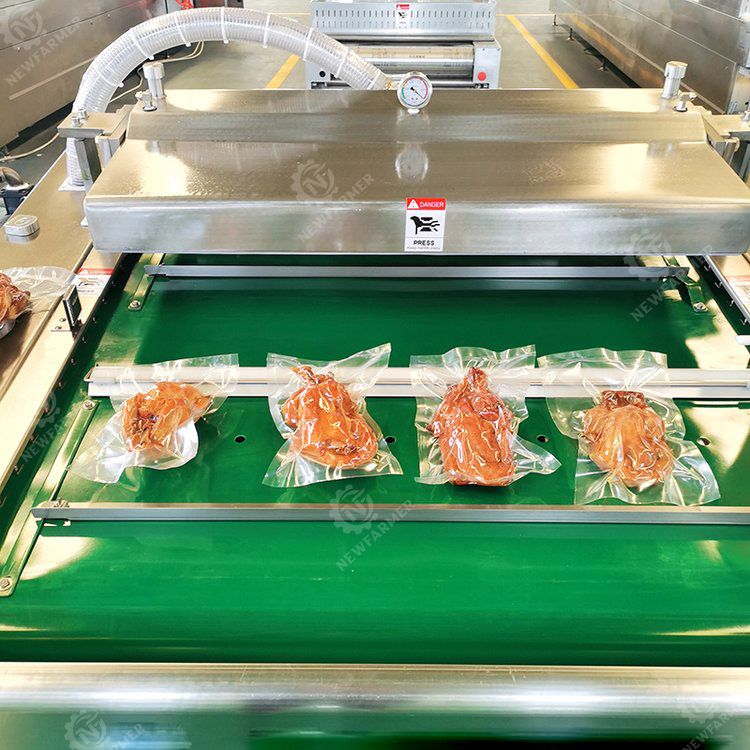

Continuous Rolling Vacuum Packaging Machine

Brand Name: NewFarmer

Capacity: 2400-3600 items/h

Power: 4Kw/380V

Apply: Used to vacuum all material, such as vegetable, fruit, foods and so on. High efficiency.

Email: info@newfarmermachine.com

Principle of the rolling vacuum packaging machine:

The rolling vacuum packaging machine is mainly composed of five parts: the upper working room, the lower working platform, the frame, the electrical system, and the vacuum system.

The continuous rolling vacuum packaging machine working process is to close the lid first, the vacuum pump pumps air from the working chamber, and when the predetermined vacuum degree is reached, the vacuum pump stops working.

Then the pressurization valve is opened, the air bag is inflated, the bead presses down to press the sealing part, and at the same time, it is powered on and heated to complete the sealing of the packaging bag.

Finally, the deflation valve is energized and opened, and the cover is automatically deflated and opened to complete a working cycle.

The advantages of continuous roll vacuum packaging machines:

- High packaging efficiency: the continuous rolling method can realize continuous packaging, which greatly improves the packaging efficiency.

- Good packaging quality: Through vacuum treatment and sealing of the sealing device, the purposes of freshness preservation, moisture-proof, oxidation-proof, and mildew-proof can be achieved, and the packaging quality is guaranteed.

- Simple operation: the control system realizes automatic PLC control and intelligent operation, and the operation is simple and convenient.

- Wide range of application: It is suitable for the packaging of food, medicine, cosmetics and other products, and has a wide range of application.

- The continuous rolling vacuum packaging machine is made of 304 stainless steel, which meets the requirements of the food processing industry and can be washed and cleaned.